Breaking into Formula 1 isn’t easy.

Thousands of students apply every year, all with the same dream. But every so often, someone does something different – something that makes the industry stop scrolling and start paying attention.

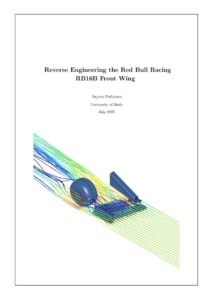

That’s exactly what did this summer. Instead of just sending CVs into the void, he set himself a challenge: reverse engineer the front wing of a Red Bull F1 car. Two months, countless hours, and a mountain of new skills later, he posted his results on LinkedIn.

The post exploded.

-

2,500+ likes

-

Comments from industry leaders

-

Real conversations that could change his future

This is the kind of initiative that turns a dream into an opportunity. And it’s a masterclass in how you stand out in motorsport.

I caught up with to hear the story behind the project, what the viral post taught him, and where he hopes this journey will take him next.

Here’s our conversation – learn and enjoy!

Background & Journey

Can you tell us a bit about yourself – where you’re studying, what stage of your degree you’re at, and your motorsport journey so far?

Hi everyone, I’m Sajana, I’m just starting my 2nd year doing Aerospace Engineering at the University of Bath. I first got into motorsport around the end of 2020 when a friend of mine introduced me to Formula 1, and I’ve been a fanatic ever since.

At Bath, I’m a member of Team Bath Racing Electric (TBRe), our Formula Student team, where I’ve been able to work on building our car and even see it race at Silverstone.

Was there a particular reason that made you say, “I want to work in Formula 1”?

Before I knew much about the sport, all the cars looked basically the same to me. It was only after I learnt a bit more about the incredible engineering behind them did I fully appreciate how much skill and knowledge goes into every detail. Not many other industries can say that they’re constantly on the cutting-edge of engineering innovation, with new designs being manufactured in a matter of days or weeks rather than months or years.

F1’s relentless pursuit of performance is something I deeply admire, and it’s exactly what I want to be a part of.

The Project

What inspired you to take on something as ambitious as reverse engineering the Red Bull RB16B front wing?

With placement season approaching, I wanted to do something that would help me stand out. A friend at TBRe, who had done her placement at Alpine, recommended I make a creative project that shows problem-solving using engineering first principles, as it would be a great experience to talk about in any interviews.

I’d seen the RB16B up close in London the previous year and had been blown away by the level of detail I saw, and so I thought it would be interesting to try and figure out why it had been designed that way, specifically its front wing.

How did you approach the project from start to finish – what tools, techniques, or learning resources did you rely on?

As you might expect, modelling the front wing wasn’t very straightforward since teams don’t release any data or dimensions on their designs. I explain the full process in my report, but in general I had to rely on lots of images and technical drawings to model the wing accurately using CAD (Computer-Aided Design).

From there, I had to learn CFD (Computer Fluid Dynamics) basically from scratch to be able to put my model in a virtual wind tunnel to see how the airflow was affected.

Every resource I used was publicly available or had free-trials, and I learnt a lot from reading forums and tutorials online, which I’ve linked in the References section of my report.

What was the hardest part technically, and what did it teach you?

The CFD was definitely the hardest part for me, as I’d never simulated anything so intricate before. I had to learn lots of new skills and techniques, and spent quite a long time learning the underlying theory behind how the process worked to make sure I actually understood what I was doing, and not simply following a tutorial.

Having spoken to more people far more experienced than me with CFD since the project, it’s obvious I only know the tip of the iceberg, but even still it’s given me a better appreciation for what the technique is capable of.

What are you most proud of when you look back at the project?

Although the simulations are impressive and make colourful pictures, it wouldn’t be possible without first making the CAD model, which is what I’m the proudest of.

I’ve been using CAD for over six years now and this is by far the most sophisticated model I’ve made. I learnt a lot of new techniques during the process, especially since I was using a software that isn’t ordinarily designed for complex surface modelling.

The Post Going Viral

Your LinkedIn post blew up – 2,500+ likes, comments from senior professionals… did you expect that kind of reaction?

Absolutely not. Honestly, I was just happy to share what I’d been doing over the summer with a few friends who I thought would find it interesting, but seeing the comments from F1 professionals and others in the industry all praising my work was very surreal.

On top of that, I’ve had loads of students like me reach out with messages telling me that I’ve inspired them to start their own projects, which is something that I’m incredibly proud of.

What did you learn about sharing your work online from that experience?

I realised that people respond far more to genuine passion and effort rather than a perfected ‘final product’. My report is by no means faultless and there were lots of limitations I faced, from not having any precise data to being a novice in the CFD field, but because the process was valuable it seemed to resonate a lot with others.

Has it opened any doors or led to interesting conversations?

Yes, I’ve been lucky enough to be offered a couple placement opportunities outside of F1, though my focus is still on that end goal.

I’ve also had the amazing opportunity to speak with legends like Professor Willem Toet about his thoughts on the project, and of course the chance to do this interview for Formula Careers, all of which have been incredible experiences that I’m very grateful for.

Looking Ahead

What’s your dream role in motorsport, and what steps are you planning over the next 12 months to get closer to it?

The whole reason I took on this project was to have something to talk about in placement interviews with F1 teams, and I’ll be sending off applications soon. My dream role would be in aerodynamics or as a design engineer, creating parts that have a genuine impact on the performance of the car.

This year, I’ll be focusing more on developing my CFD and CAD skills at TBRe, ready for any opportunities I have the following year.

Message to Others

What advice would you give to other students or career-switchers who are desperate to get into motorsport but don’t know where to start?

The industry is all about having experience. Join a student team if you can, and start relevant personal projects to help you stand out from the crowd. They don’t have to be big, just focus on starting small and go from there. Everything you do builds confidence and skills, which shows your passion.

Also, don’t underestimate the power of putting your work out there, as opportunities often come from being visible.

If someone reading this interview wanted to follow your example, what’s the first step you’d tell them to take?

Pick a project idea that really excites you, and commit to finishing it. By no means does it have to be perfect, but the willingness to learn and develop new skills is what teams really look for. Document it, share it online, and connect with others in similar positions.

The hardest step is taking the initiative, and from there opportunities have a way of following.

Thank you Sajana for sharing your journey with us, and for inspiring us in our quest to work in one of the most exciting industries in the world.

- You can connect with Sajana on LinkedIn here: https://www.linkedin.com/in/sajanapathirana/

- You can view Sajana’s project in full here: https://www.linkedin.com/feed/update/urn:li:activity:7358605346531119104/

For all student placements please visit our student placement portal.